Frame & Body

Strength and Longevity in Trailer Frames and Bodies

Durability should always be your primary consideration when buying a trailer. The strength and dependability of your trailer’s Frame & Body are crucial in ensuring that you can do the operation quickly and safely, whether you're transporting large cargo for work or leisure. The caliber of the materials used in a trailer's construction is one of the most important aspects affecting its longevity. Over time, purchasing a high-quality trailer constructed from premium materials will help you save money, time, and stress. There are many possibilities available if you're in the market, ranging from entry-level devices to sophisticated ones tailored for particular industries.

The Foundation of Load Capacity

In the logistics and transportation sector, trailers are a crucial instrument that are frequently utilized. And one of the most important elements in creating a sturdy trailer is the body construction. The several parts that comprise the trailer body are referred to as structural parts.These parts include, but are not limited to, the following:

-

Frame: The trailer's frame acts as its skeleton, supporting the vehicle's weight and load. It must be strong and rigid to ensure stability and safety during transportation.

-

Carriage: The trailer's carriage is the goods-loading space, requiring enough strength and stability to protect items during transport.

-

Connectors: Trailer connectors, like bolts, joints, and supports, link and reinforce body parts to ensure structural stability and reliability.

The trailer's engineering and design are additional crucial elements. Wear can be reduced and load management enhanced with the use of aerodynamic forms and stress-distribution strategies. Because more axles distribute weight more uniformly and lessen the pressure on individual components, axle placement and quantity are also important considerations.

To guarantee the durability required for long-term transportation of heavy loads, the trailer's build quality, smooth joints, precision welding, and conformity to industry norms are essential. Under extreme strain, minor flaws in the material or design could jeopardize the trailer's structural integrity. Don't you find it intriguing how load mastery is determined by engineering precision?

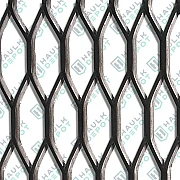

Material Choices for Frames

The structural strength, overall weight, and anticipated lifespan of a trailer are determined by the materials used in its construction. Steel is a popular material for trailer construction because of its great resistance to weight and durability. Every steel product exhibits unique characteristics. How well a frame withstands everyday load depends on the type and thickness of steel chosen. High-strength steel is the main material used in trailers for demanding applications because it offers the best defense against bending damage and pressure-related destruction.

Aluminum frames are available on the market because they are lightweight and durable, two important features. Because of its high corrosion resistance, the material can be used in trailers that are used in damp and coastal environments. Because aluminum does not rust like steel, it can withstand major damage to the trailer's construction, giving it a longer lifespan. Despite aluminum's exceptional durability and corrosion resistance, steel outperforms aluminum in terms of strength when handling big loads.

Inspection and Maintenance Routines

Keep your trailer body in good condition by checking for damage, cleaning to stop corrosion, lubricating moving parts, and maintaining the flooring, roof, and lights. To increase its lifespan, take quick care of rust, make sure everything is aligned correctly, and do routine preventive maintenance.

1. Regularly Inspect for Structural Damage

Checking the trailer for structural damage on a regular basis is one of the most important parts of trailer body maintenance. Examine the trailer's structure, sidewalls, and roof for any indications of wear and tear, including cracks, dents, and rust.

Since they are frequently the first regions to exhibit signs of stress, pay close attention to the areas surrounding joints and welds. It's important to take care of any damage you find right away. If ignored, little fractures can easily develop into serious structural problems. At least once a month, we advise giving your trailer's body a complete inspection. By being proactive, you may save costly trailer repairs and identify issues early.

2. Keep the Trailer Clean and Free of Debris

Keeping the trailer body clean is important for preventing corrosion and other types of damage, so it's not just for show. Rust and corrosion can result from dirt, grime, and road salt building up on the trailer's outside and undercarriage.

To get rid of these dangerous materials, you must regularly wash your trailer, especially in the winter. To clean difficult-to-reach places and get rid of any dirt, use a pressure washer. The underside of the trailer is especially prone to rust and is sometimes overlooked, so pay attention to it. To prevent rust, think about giving the trailer's exterior a protective coating after washing.

3. Lubricate Moving Parts and Hinges

Your trailer's moving components, like the doors, hinges, and locks, need to be lubricated on a regular basis in order to operate properly. These parts may get stiff and finally fail without enough lubrication, necessitating expensive repairs or replacements.

At least once a month, lubricate all moving parts with a premium lubricant made for demanding uses. This little action can prolong the life of your trailer's parts, stop wear and tear, and guarantee that doors and locks work properly.

4. Inspect and Maintain the Roof

Your trailer's roof is vulnerable to leaks and other damage because it is frequently exposed to inclement weather. Preventing water damage to the trailer's contents requires routinely checking the roof for wear indicators like fractures, punctures, or loose seals.

If you discover any problems, fix them right away using the proper patching materials or sealants. Consider using a UV protectant on trailers with fiberglass or rubber roofs to shield them from the sun's rays. To make sure the roof of your trailer stays in top shape, we advise making an appointment for a professional roof inspection at least twice a year.

5. Check and Maintain the Trailer’s Lights

Proper lighting is critical for the safety of your trailer on the road. Faulty lights can lead to accidents and costly fines, so it's essential to regularly check that all lights, including brake lights, turn signals, and reflectors, are working correctly.

Inspect the wiring for wear or damage, and replace any burned-out bulbs immediately. Consider upgrading to LED lights, which are more durable and energy-efficient than traditional bulbs. It’s preferable to access comprehensive trailer lighting inspections and repairs to ensure your trailer meets all safety standards.

Future Trends in Trailer Design

In conclusion, the direction of material science and technology advancement is creating an interesting environment for trailer’s Frame & Body design in the future. In addition to improving trailer performance and economy, lightweight composites, intelligent materials, and sophisticated automation are opening the door for more intelligent and sustainable transportation options. More fuel efficiency, safety, and adaptability are being fostered by these developments, all of which are essential for satisfying the changing needs of international logistics and environmental rules.

These trends have the potential to revolutionize industry norms and spur innovative approaches throughout the transportation sector as they pick up steam. Trailers' longevity, sustainability, and operational effectiveness will all be improved by the incorporation of cutting-edge materials and technology, guaranteeing that they continue to be vital instruments for contemporary logistics. The industry may reach previously unheard-of performance levels and keep changing to meet the opportunities and challenges of the future by adopting these advances.