Braking System

Ways to Optimize Trailer Performance with Reliable Braking Systems

Safety should always be the first priority when towing a trailer. The Braking System is an important part of safe towing, and knowing the parts that make up a trailer braking system is crucial to ensuring safe and comfortable travel. In this write-up, we will look at the many types of trailer brake systems and the components that keep them running effectively.

Introduction to Trailer Braking Systems

Electric trailer brakes operate by applying brakes to the trailer in response to the braking action of the tow vehicle, using an electronic brake controller installed in the truck's cab. When the driver applies the brakes, the controller signals the trailer's electric brakes, which apply the brakes with the same force as the tow vehicle.

To apply the trailer brakes, electric trailer brakes transform the electrical current coming from the brake controller into mechanical force. Each brake assembly has an electromagnet that is activated when the brake controller signals the trailer brakes. After that, a lever will be pulled, applying the brake shoes to the drum. The braking force increases with the amount of current applied to the brakes.

What is a Trailer Brake Controller?

In addition to controlling the tow brakes with a trailer brake controller, the driver can keep an eye on the trailer's movement from the cab of the vehicle.

Two trailer brake controllers are available for consideration:

-

Inertia-Based Brake Controller: An accelerometer is used by the inertia-based brake controller to detect the inertia of the vehicle and modify the trailer brake pressure according to momentum.

-

Time-Based Brake Controller: A time-based brake controller is less accurate than inertia-based systems, but it activates the trailer brakes as the tow vehicle brakes and increases pressure progressively based on driver settings.

You can choose from a variety of towing safety equipment while looking for trailer brake controller solutions. They consist of trailer sway control hitches, electronic trailer brake controllers, brake controller wiring, and much more.

The Structure of Trailer Braking Systems

The trailer brakes themselves are, of course, the central component of any dependable trailer braking system. However, it is composed of additional specific system counterparts:

Hubs & Wheels

Although they are sometimes disregarded, your trailer's wheels and hubs are essential to the braking system. When necessary, the brakes will engage smoothly and effectively thanks to high-quality hubs and well-maintained wheels. To find any wear or damage that can impair braking ability, it's critical to regularly inspect the hubs and wheels of your trailer.

Trailer Wiring

The trailer wiring system makes it possible for your towing vehicle and trailer to communicate reliably. Through this cabling, the trailer brakes can receive signals from the brake controller and be activated in unison with the vehicle's braking system. For smooth brake functioning and general road safety, make sure your trailer wiring is fitted correctly and in good condition.

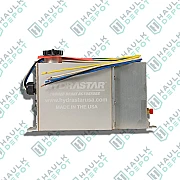

Brake Controller

To control the braking system of a trailer being towed, a trailer brake controller is a device mounted in a tow vehicle. Regardless of the vehicle's brakes, it allows the driver to regulate the amount of braking force applied to the trailer. This helps preserve stability and control by making sure the trailer's brakes engage to prevent it from pushing or swaying the tow vehicle, which is especially crucial when towing heavy loads or traveling downhill.

Comparing Electric and Hydraulic Systems

Electric brakes, the most popular kind of trailer brakes, are activated as necessary by electrical signals from the tow vehicle. Their popularity can be attributed to their ease of use, precision control over the brakes, compatibility with the majority of automobiles, and ease of adjustment. The only significant drawback is that in order for them to function, your vehicle and trailer must be electrically connected.

Both hydraulic brakes and surge brakes use hydraulic pressure to engage the trailer brakes, which makes them quite comparable. The distinction is that a separate hydraulic brake system within the trailer is necessary for hydraulic brakes. They can better manage heavier loads and bumpier roads because of this difference. The hydraulic fluid inside the master cylinder of this brake system is pressurized when the brakes are applied. It is attached to the brake pedal of the tow vehicle. The fluid activates the brakes and slows the moving trailer as it passes through the lines and assemblies.

Advantages of High-Performance Braking Systems

When compared to conventional braking systems, high-performance brakes are designed to offer more stopping power, durability, and responsiveness. They are made to withstand harsh circumstances and higher temperatures.

-

Better Heat Dissipation: Especially while handling big loads or on steep terrain, high-performance brakes disperse heat more efficiently, reducing brake fade and guaranteeing dependable operation.

-

Better Responsiveness: This feature improves the overall driving experience by offering confidence in a variety of driving conditions, from city traffic to highway cruising.

-

Increased Durability: High-performance brakes, which are made from cutting-edge materials like carbon composites or ceramics, resist wear, last longer, and lower repair costs.

In general, the advantages frequently outweigh the disadvantages. Over the course of the vehicle's life, the greater durability results in fewer replacements and maintenance, saving money. By preventing accidents, the enhanced performance may save money on expensive repairs.

Maintenance Practices for Reliable Performance of Trailer Brakes

To keep your rig safe while traveling and out of the mechanic's shop, a little preventative maintenance can make a big difference. Even an amateur can manage many of the steps, but there are some that are best left to the experts. We go over some fundamental trailer brake repair procedures and advice below:

-

Inspect the Braking Components

Check your braking shoes, rotors, drums, and pads for wear and tear on a regular basis. It's imperative to repair the impacted parts right away if you observe any severe damage or uneven wear. Ignoring worn-out brake parts can result in less effective stopping and jeopardize your road safety.

-

Replace Brake Fluid

Find your vehicle's brake fluid reservoir behind the hood, then check the fluid level. Make sure it falls within the range that the reservoir recommends. Carefully add the suggested type of brake fluid if the level is below the ideal range. Debris and moisture can contaminate brake fluid, reducing its effectiveness.

-

Maintain Pad and Rotor

If they are worn down to the acceptable minimum thickness, replace them. Examining the state of the rotors is also crucial when changing brake pads. Look for indications of unevenness, scoring, or warping in the rotors. To ensure smooth and effective braking, think about resurfacing or replacing the rotors if they show any of these problems.

-

Check Out Warning Lights

The dashboard warning lights on a contemporary vehicle will notify you of possible problems. Get your braking system checked out right away if the brake warning light comes on. Low brake fluid levels, ABS (Anti-lock Braking System) issues, or other brake-related issues may be indicated by the warning light.

In conclusion, this is crucial for any towing operation since you should prioritize the safety of your trailer brake system. Investing in reliable systems and inspections, regardless of whether you choose hydraulic or electric brakes, will provide you piece of mind and dependability on all of your travels. Make sensible choices!